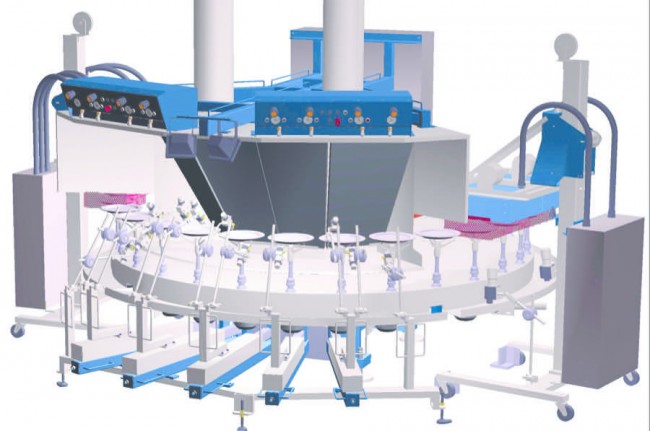

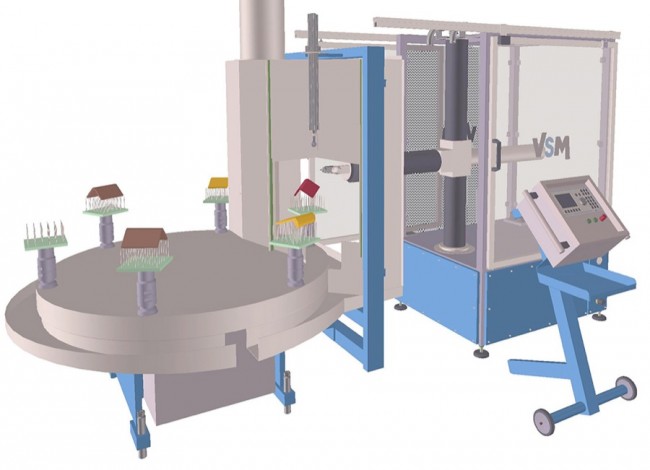

Spraying vitreous or porous ceramics, also in 2 colours. The machines have spindles on a round table. The carrousel diameter can be from 900 up to 2900 mm. With 3 up to 36 rotating spindles.

Porous Ceramics

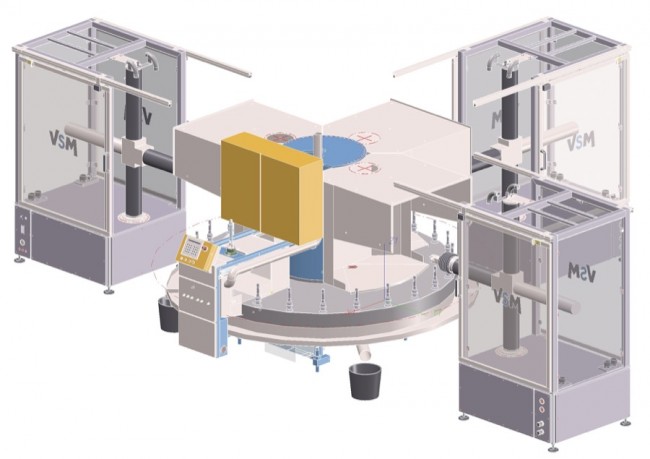

SPRAYING GLAZE ON VITREOUS CERAMICS

Spraying on earthenware, stoneware and porcelain in one or two colours. Both static spraying and robotic spraying are used here. As well as dipping a colour outside, before or after spraying the inside.

SPRAYING GLAZE ON POROUS CERAMICS

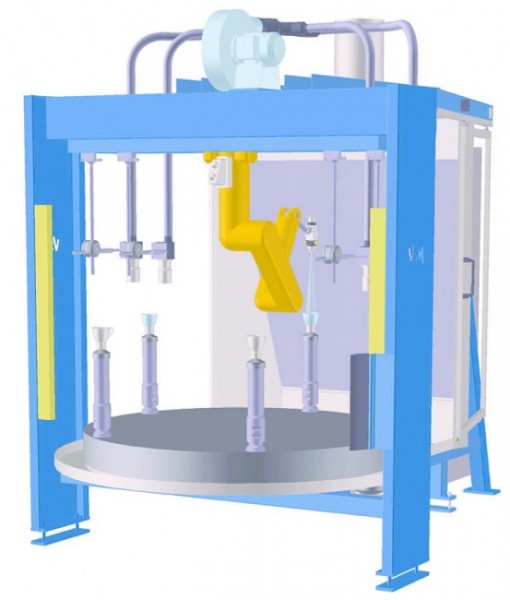

Our rotary table glaze spray machines are always unique machines, fully adapted to the production process of the customer. After all, every customer has specific requirements. In many cases our engineers are requested to design a specific solution. We can do so very economically due to our modular designs. Herein lies our strength: we can meet all your requirements for the spraying of ceramics, especially dinner and clay-ware. Ask the comprehensive brochure for all technical details and options. The Multispray is designed for fully automated glazing of ceramic products of various shapes and sizes. The machine is fitted with product spindles on a turn-table and a number of spray booths and spray guns. Thus allowing for quick simultaneous spraying of large numbers of products, in up to four different colours. There are multiple ways to colour the ceramics, two spray options are explained on the other page. Also robots can be added to the multispray, for flexible automation. The spraying process is automated, fast, clean, and also economical due to the collection of glaze, so you can re-use it. An optional extraction unit that circulates the filtered air back into the build- ing can be added. Various types of product support can be mounted on the spindles easily and quickly interchangeable. Due to our modular design, our big experience and many options, you can automate virtually any production.

THE ADVANTAGES

- Spraying large numbers of ceramic products in many shapes and sizes;

- Accurate and infinitely repeatable production;

- Spraying up to four different colours;

- Clean spray process with re-use of glaze;

- Modular design, with many options;

- Very high life-span with minimum maintenance;

- Turn-key delivery possible;

- User-friendly because of easy programming and cleaning, so fast change overs;

- A fully equipped test facility at VSM for optimum advising purposes;

- Specials up on request.

PHOTOS

MULTISPRAY WITH STATIONAIRY SPRAYGUNS

A fully automated spray machine with product spindles on a round turn-table, spray booths and stationary spray guns. With this machine you can quickly spray large series of products. The ceramic products are placed on revolving spindles with product supports, and are positioned in front of the spray booths.

THE ADVANTAGES

- Big productions with short cycle times;

- Multiple spray guns possible.

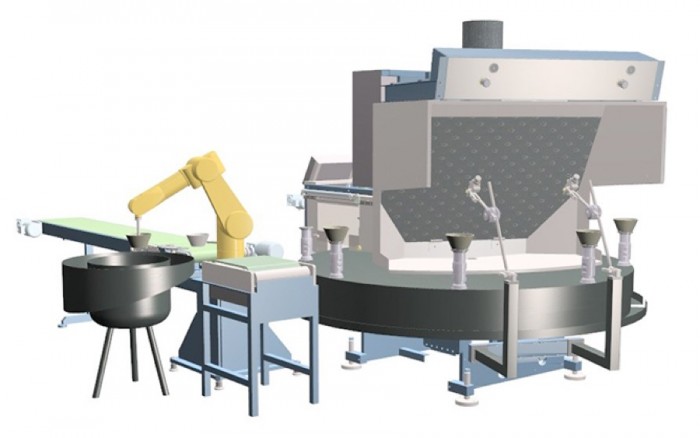

MULTISPRAY SPRAYING WITH ROBOT

The Multispray Robot (M-R) uses the multisprays round-table, spray booths and spindles as basis. It is equipped with one or more robots which moves the spray gun. Because of the many angles in which the spray gun can be directed at the product, the product can be sprayed on all sides. This makes the robot extremely flexible and especially suitable for the spraying of handles on cups and irregular products. With this system you have a superb and flexible automatization of your production. The combination can be made by one or more Kuka, other commercial or VSM Coat-A-Flex robots. Several configurations are possible, depending on the number of required fixed and flexible spray guns and the colours to be sprayed. With the M-R it is possible to spray irregular shapes very fast and accurately.

THE ADVANTAGES

- Irregular products can be sprayed from all angles;

- Superb spraying quality with one or more robots for fast, repeatable production;

- Very flexible and suitable to fit in any production line;

- ‘Just In Time’ (JIT) delivery with high, repeatable quality products is possible;

- Short change-over times, as all settings of the spray guns are stored into the computer.

THE OPTIONS

- Cup handle aligning;

- Automated load and unload;

- All other Multispray options;

- Turn-key delivery possible.